|

|

| How To Choose Appropriate Material When Starting A Basin Factory? |

|

|

| |

Key Word:Taili Plastic Machinery, Injection Molding Machine, Interests, Plastic Basin Manufacturing Factory, Material Selection

A few days ago, a customer called to ask, what kind of raw materials are more suitable if he wants to start a basin factory.

There are a great number of various plastic materials, which can be chosen from. Let's take this opportunity to talk about it today:

1. What material to choose?

Plastic raw materials used in industrial production generally include five types of general plastics, namely, polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polystyrene (PS) and ABS plastics.

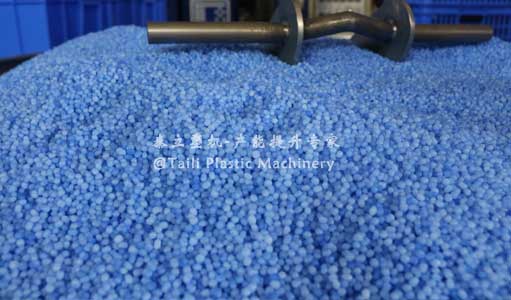

Generally, the material used for plastic basin is polypropylene, a kind of thermoplastic polymerized by propylene. The properties of PP material ensure its strong fall resistance and toughness. Therefore, polypropylene PP material is generally the main production material for plastic basin production.

In addition, one or more toners can be added to increase the aesthetics of the plastic basin. (In addition, in the plastic industry, color fillers are generally toner and color masterbatch, in which the cost of color masterbatch is high, while the color reduction degree is relatively higher. There are many different color filling materials for different markets)

2. New material or recycled material?

In the production process, if the quality requirements are relatively high, we generally consider using new materials.

However, in the actual production process, most manufacturers in Shandong and Yiwu will choose recycled materials, because the price of recycled PP (polypropylene) is generally 5-6000 yuan per ton, while the cost of new materials is generally more than 8000 yuan.

However, some manufacturers require highly for quality stability, thus they prefer to choose new materials for processing.

In the process of using recycled materials, be sure to pay attention to the filtration of the nozzle, as the nozzle and runner are easy to get block!

Generally speaking, it is recommended to use cold flow channel for washbasin with return material, which is not easy to block the nozzle.

To sum up, in order to engage in the processing and production of plastic pots, we can choose to use polypropylene PP material and purchase a return mixer. In the production process, we can use return material appropriately.

When you have bought the Taili injection molding machine, peers got urgent at your upgraded interests!

Follow Taili Plastic Machinery and we will share more with you. |

|

China

China

China

China