Key Word: Taili Plastic Machinery; Taili Plastic Machinery-Capacity Improving Expert; Efficient; Stable; Flash; Lack of Material

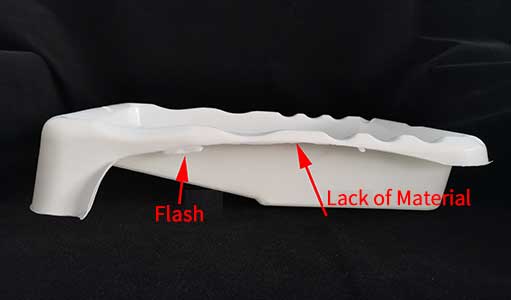

Yesterday, a friend contacted Taili Plastic Machinery and said that he encountered an epic problem: his products are always of different problems, with flash and lack of materials at the same time. How can he adjust to go back to the normal production?

1. Whether the mold center is offset

If there is flash on one side and lack of material on the other side of the plastic part, the eccentricity of the mold can be considered first, which leads to uneven distribution of f runner, resulting in flash and lack of material on the product surface at the same time. Secondly, it is necessary to consider the eccentricity caused by excessive injection pressure, poor fluidity of raw materials or mold machining accuracy.

2. Observe the mold inlet

The unreasonable design of the product runner is also one of the key reasons, which results in flash and lack of material appearing at the same time due to the product length diameter ratio deviation.

It is obvious that two inlets of the product are too far away from each other, and the distribution of the length diameter ratio of the product is unreasonable, which leads to the disturbance of the fluid in the middle.

3. Increase the temperature

If the product conditions permit, we can increase the melting temperature in the barrel appropriately. In general, for most engineering plastics in the molten state, material temperature change of every 10Ōäā will bring the fluidity (MFR) deviation of about more than 100. On the premise of optimizing the fluidity of the product, the filling speed of the injection molding machine can be increased to make up for the shortage of the mold.

Taili Plastic Machinery always keeps in mind that what a good injection molding machine factory should do is to help improving the capacity and boosting the profits, rather than offer the similar products the customers need. This is also what Taili Plastic Machinery keeps doing.

Follow Taili Plastic Machinery and we will share more with you. |

China

China

China

China