|

|

| Taili Machinery-Practical Solution for Plastic Food Container |

|

|

| |

Key Words: Taili Machinery, Food Container, Plastic, Thin-Wall, High-Speed, Short Cycle Time, High Performance-Cost Ratio, Good Quality

I. Product Parameters

Table 1. Manufacture Line Design for Food Container (Box)

| Item |

Plastic Food Container (Lid) Manufacture Line |

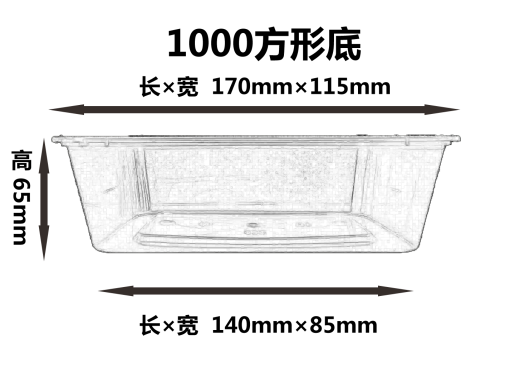

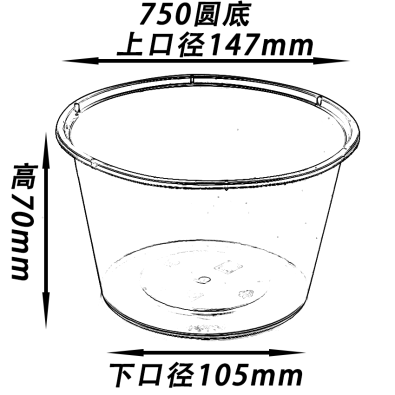

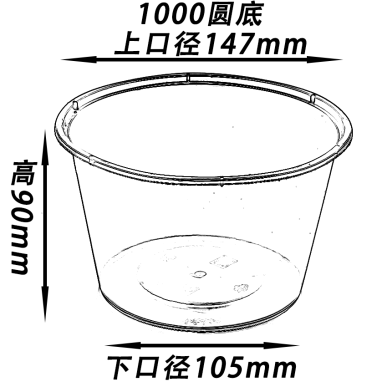

| Sample |

|

| Cavity |

750ml Box/Bowl: 6 1000ml Box/Bowl: 4 |

| Sample Weight |

750ml Box/Bowl: 12.5g 1000ml Box/Bowl: 15.5g |

| Cycle Time (including mold cooling time) |

750ml Box/Bowl: 6 cavs, 4.5-5s/mold 1000ml Box/Bowl: 4 cavs, 4.5-5 s/mold |

| Power Consumption |

0.00065 kWh/g |

| Machine Type |

TLG-420 (750ml Box/Bowl) TLG-360 (1000ml Box/Bowl) |

| Stability Test Standard |

When the machine works in a stable condition, put a cigarette on the machine and it wonât fall down. |

Table 2. Manufacture Line Design for Food Container (Lid)

| Item |

Plastic Food Container (Lid) Manufacture Line |

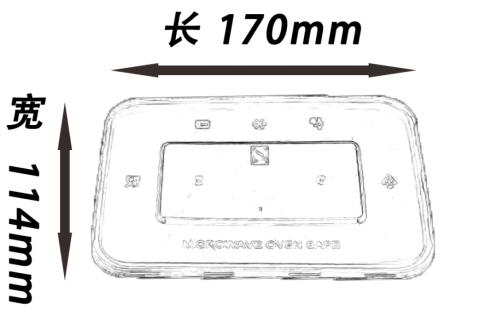

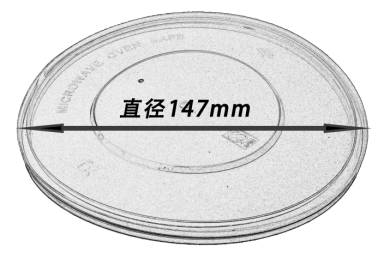

| Sample |

|

| Cavity |

Lid (for box/bowl) 8 |

| Sample Weight |

Lid (for box/bowl) 7.5g |

Cycle Time

(including mold cooling time) |

4.5-5s |

| Power ConsumptionïŒkwh/gïŒ |

0.00065 |

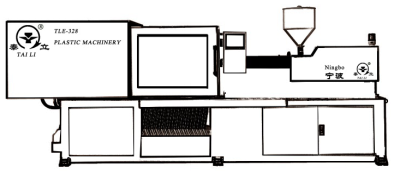

| Machine Type |

TLG-400 (specialized for lid) |

| Stability Test Standard |

When the machine works in a stable condition, put a cigarette on the machine and it wonât fall down. |

| Maximum Mold Switch Time |

2.5 |

| Metal Sheet (Simplified) |

|

| Color of Metal Sheet |

White and Blue |

| Machine Size (LĂWĂH) |

4.5Ă1.48Ă1.9 |

II. Features & Advantages

1. Rich Experiences

As a high-tech enterprise which specializes in producing injection molding machines, we have over-20-year experiences in manufacture, sales and service. Our factory is made up of five workshops, namely, Cast Machining Shop, Steel Parts Machining Shop, Frame Sheet Metal Fabrication Shop, Installation & Adjustment Workshop and Painted Workshop. Our workers and staff are equipped with rich designing and producing experiences, which guarantees us with strongly independent product-design capacity as well as far-reaching reputation at home and abroad. We will offer refined service and testing technology for each customer who choose Tailke Machinery, to assure each machine âwork easily, run smoothlyâ.

2. Customization Service

We can customize machine type, sheet metal and adjust service for each customer. Further during using, we can offer more advices to refine machine parameters, which will increase machine efficiency and prolong using lifetime.

3. Unique Solution Design

For each customer, we will offer a refined solution. With the help of Big Data analysis, we will focus on the information of sample product and chosen material, to design the optimal machine and offer a refined solution design, including production cycle time and average weight deviation.

4. Big Data Service

We can offer a Big Data acquisition system for each customer. On the base of the result from big data analysis, we can refine the parameter and help to guide our customer transfer from tradition factory into intellectualized unmanned factory.

5. Superior Service

With the service tenet of âprofessional, concentrated, absorbed, attendedâ, we select and require professional technical service personnel to concentrate on the adjustment technology of injection molding machine system and product, and further to provide a customized solution for each customer. With the ideal of âQuality and Service go firstâ, we hope to provide each customer with the most professional technology support, and help them away from the complicated data analysis and parameter refinement.

III. Adjustment & Maintenance

1. Before purchasing, we can offer a customized solution for free and help to determine a refined machine and purchasing plan, at the aim of reducing the investment and further increase the product profits.

2. Before purchasing, we can offer the free experience of sample mold (mentioned within the solution design) and take video of the machine work on the spot. We will also invite the customer to inspect the mold.

3. When the machine arrives, specialized professional technicians will adjust the machine on the scene, to assure the machine âwork easily, run smoothlyâ.

4. After delivering, we will edit customerâs information into the high-speed machine maintenance record system. Door to door maintenance will be arranged regularly, to increase the machine efficiency, prolong the using lifetime and reduce the malfunction rate.

5. When practical production starts, we will communicate with customer regularly, to refine the parameter and increase product stability, which further helps to increase production efficiency and boost profits.

6. âOne to oneâ adjustment and maintenance service will be offered during the real-time production. Technicians will give technical guide and support after the machine gets into production. On the base of sufficient understanding of customerâs daily production, we will help them away from the complicated adjustment process and further lay a foundation for the development of automated unmanned factory |

|

China

China

China

China