Key Word: Taili Plastic Machinery; Taili Plastic Machinery-Capacity Improving Expert; Efficient; Stable; Wrong Adjustment

A few days ago, Liu who had just stepped into the injection molding machine adjustment industry, told Taili Plastic Machinery that he had just resigned and left because of the machine adjustment error, resulting in a large area of scrapped products.

The factory Liu used to work in produces disposable knives, forks and spoons. The mold has 32 cavities. The weight for single piece of product is 2g. The product is specialized for foreign customers. The general cycle is controlled as about 10 seconds.

Mr Zhou, the technician of the last shift left in such a hurry for home that he didn't tell Liu that he had just repaired the mold. Liu didn't pay attention to it, either. Unexpectedly, there was a lack of material in one cavity, resulting in a large number of waste products.

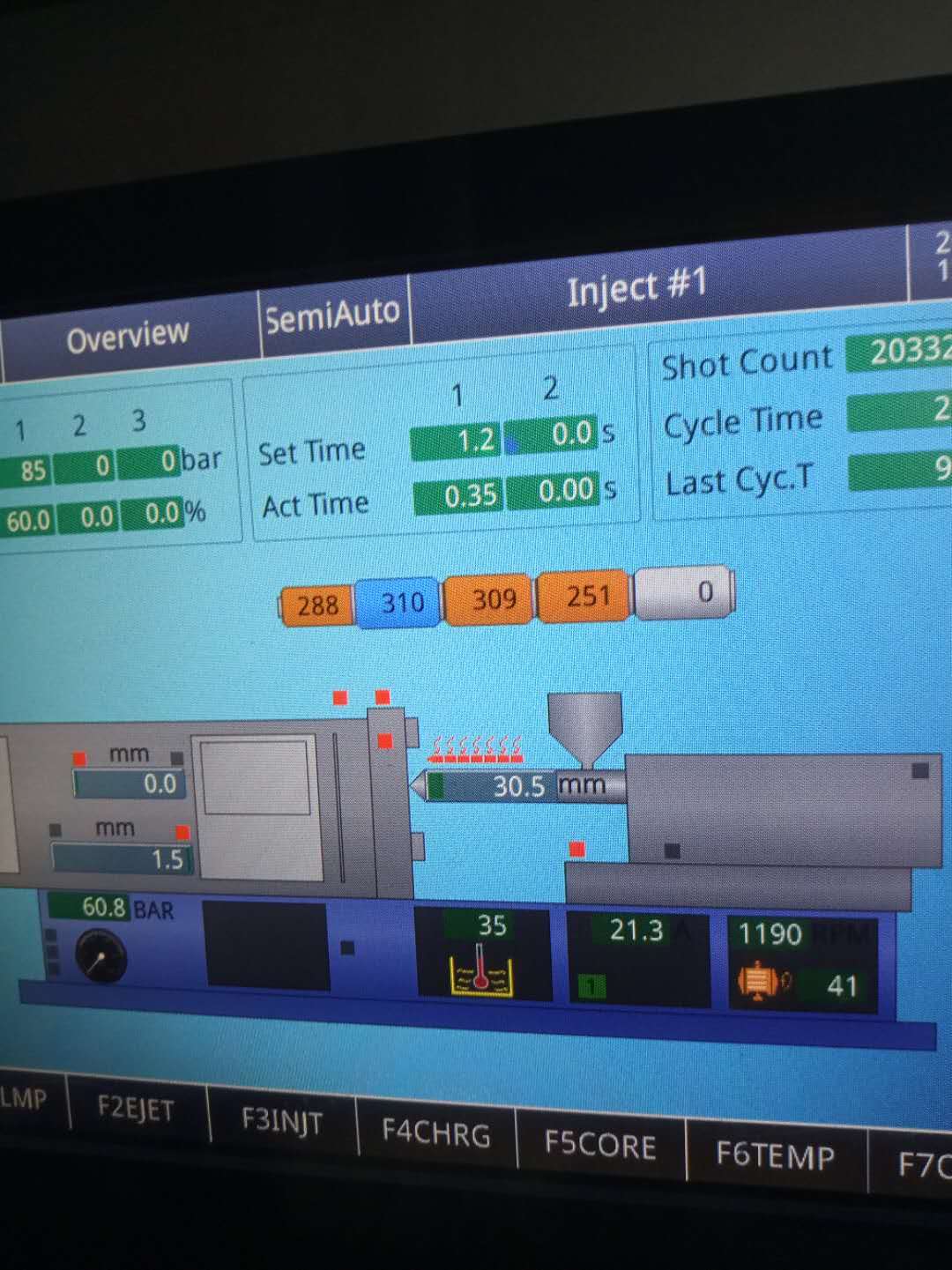

Mr. Liu showed us the pictures of injection molding machine parameters saved on his mobile phone as follows.

It can be seen from the picture that the temperature of the last section of the injection molding machine is very low, which does not meet the standard of setting the barrel temperature of the general injection molding machine. Generally speaking, the temperature of the last three sections of the injection molding machine should be similar, or arranged from high to low. In most cases, the problem of too low temperature in the last section will not cause the alarm of the injection molding machine. Therefore, if we do not pay more attention during the inspection, we are likely to miss this problem.

When the temperature of the last section is too low, the storage process of raw materials will not be sufficient, which will lead to unstable product production. There may be a large area of shortage of materials, or a shortage of materials of single product.

In fact, we had dealt with a similar problem some time ago. The treatment method is very simple that you don’t need to replace the heating ring or the thermistor. Just close the cooling water distributor at the end of the barrel. A lot of adjusting machine technicians who are not engaged in thin-wall high-speed production may not notice that because the cycle time is too short in the production process of thin-wall products, the temperature at the end of the barrel may drop too fast. On the contrary, according to their common experience, they won’t close the cooling water at the end of the barrel.

Taili Plastic Machinery always keeps in mind that what a good injection molding machine factory should do is to help improving the capacity and boosting the profits, rather than offer the similar products the customers need. This is also what Taili Plastic Machinery keeps doing.

Follow Taili Plastic Machinery and we will share more with you. |

China

China

China

China