|

|

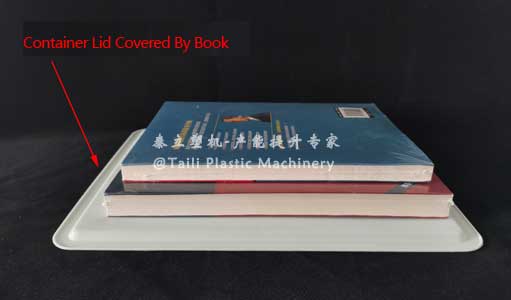

| Record 79’╝ÜPut A Book On the Injection Molded Product? Let The Product Read More And Get A Higher Price? |

|

|

| |

Key Word: Taili Plastic Machinery; Taili Plastic Machinery-Capacity Improving Expert; Efficient; Stable; Storage Box

A few days ago, Taili Plastic Machinery went to visit Mr. Wu's factory in Jiangxi Province, whose main product is storage box. The purchaser is a famous foreign brand, who is very strict with the product quality, delivery time and price.

Mr. Wu's product is made of ordinary PP (polypropylene) materials, doped with certain recycled materials. Strangely, after each product is produced, Mr. Wu will press it with a book for 30 seconds, and then release it when itŌĆśs completely cooled. Does he aim to make the product read more so as to sell at a higher price?

In fact, this is the way that Mr. Wu came up with to ensure that the product panel does not warp. Although It's a little bit troublesome, it is quite effective. In view of Mr. Wu's problem, Taili Plastic Machinery puts forward the following solutions:

1. Check the nozzle and feeding mode

Aiming at the problem of warpage of large flat injection molding products, it is generally suggested that the number of nozzles of products can be increased to reduce the flow length ratio of products and increase the degree of directional arrangement of PP fluids, so as to minimize the harm caused by warpage. If the conditions permit, the large nozzle is not prone to warping. The small nozzle is more prone to warping when the fluid fluidity is poor.

2. Increase the mold temperature

If the profit margin allows, you can use mold temperature machine to increase the mold temperature or reduce the amount of cooling water. The warpage of large flat products is mainly caused by the rapid cooling of the product surface and the different internal shrinkage of the product.

3. Lower the temperature and raise the speed

For this type of product whose mold is determined by the purchaser, the material temperature of the product should be reduced as far as possible, the injection speed should be increased, the injection pressure should be reduced, the injection should be completed in the shortest time, and the pressure holding time should be increased at the back end of the injection, so as to minimize the warpage of the product and reduce the cost of manual inspection.

Mr. Wu adjusted according to the above ideas, and sure enough, the shrinkage rate was greatly reduced, and normal production could be achieved without book pressure.

Taili Plastic Machinery always keeps in mind that what a good injection molding machine factory should do is to help improving the capacity and boosting the profits, rather than offer the similar products the customers need. This is also what Taili Plastic Machinery keeps doing.

Follow Taili Plastic Machinery and we will share more with you. |

|

China

China

China

China