Key Word: Taili Plastic Machinery; Taili Plastic Machinery-Capacity Improving Expert; Efficient; Stable; PET product; Shrinkage; Deformation

Shandong's Mr. Liu has been tucking with me through WeChat: he has recently came crossed into troubles in making perfect products. The adjusting master told him that the slower the PET type products were, the better the products would be. Mr. Liu did according to the masterās words. However, he still failed and the products still shrunk and deformed. Thus, he contacted Taili Plastic Machinery to consult the solution.

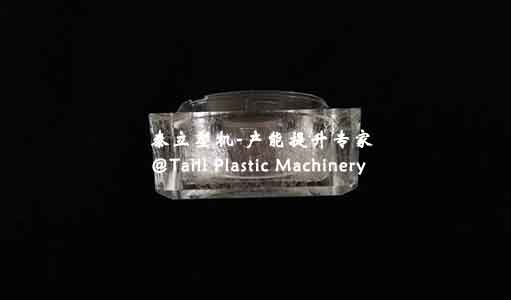

As shown in the figure below is the product produced by Mr. Liu. PET products are usually not molded directly due to material limitations. Generally, PET products are mostly used to make bottle preform. In the production of bottle, the preform is at first made by injection molding machine and then the preform is blown to the bottle commonly seen in our daily life. However, the modified PET material has better material properties, and the packaging products can be produced well with the specialized injection molding machine.

After a close look to the product, we found that Liu's product had very serious shrinkage marks on the surface. Generally, the shrinkage of the product surface is mainly caused due to the uneven distribution of internal stress in the product surface material and inner core material. There is a kind of idea among many adjusting masters that we can decrease the injecting rate to produce qualified PET products whose wall thickness is thick, then add pressure maintaining to form a supplement. Thus, the shrinkage and deformation will be avoided.

In fact, the above idea is wrong.

For products with surface accuracy requirements, the faster the injection rate and the injection pressure is, the better the product will be. The reason is that the faster the injection speed is, the smaller the difference between the surface temperature and the center temperature of the fluid is. After the overall demolding, the overall shrinkage will be formed, the surface accuracy of the product is thus improved.

For PET products, the multi-level injection method is generally used, which is to inject slowly in the material channel, and keep the cold material in the material channel as much as possible. When filling the mold cavity, the injection rate should be increased as much as possible to greatly improve the accuracy of the product surface.

Therefore, we told Mr. Liu that your shunting master only knew some aspects and did not know them all. The process of debugging PET products must follow this multi-level injection method, which can achieve the best effect.

I went to the plant and adjust according to the idea. After the parameters are reset, as expected, the product surface immediately became smooth and clean.

Taili Plastic Machinery always keeps in mind that what a good injection molding machine factory should do is to help improving the capacity and boosting the profits, rather than offer the similar products the customers need. This is also what Taili Plastic Machinery keeps doing.

Follow Taili Plastic Machinery and we will share more with you.

|

China

China

China

China