Key Word: Taili Plastic Machinery; Taili Machinery-Capacity Improving Expert; Helmet; "One Helmet and One Belt"

Since May 15, injection-molded driving helmet market has entered a crazy state. All manufacturers with stocks are raising their price, while the stocks of helmets in various wholesale markets almost run out.

Mr. Li contacts me through WeChat: He wanted to join this business and wanted to make a driving safety helmet that meets the national standard. He told me he didnāt know how to start the business. Here, I take this opportunity to make a knowledge popularization for all friends who are considering to enter this industry.

At present, a standard driving helmet must pass the China Compulsory Certification 3C standard, among which the most important parameter indicators are: collision energy absorption performance and penetration resistance performance.

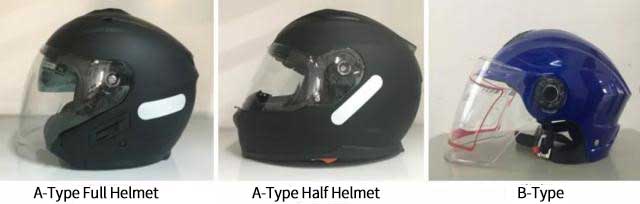

China's current standards divides helmet into two categories: A-type helmets and B-type helmets according to different applicable objects. A-type helmets are suitable for drivers of motorcycle with a total displacement of more than 125cc. A-type helmets are further divided into full and half helmets. B-Type helmets are suitable for drivers of motorcycle with a total displacement of less than 125cc. Their volume and weight are less than those of A-Type helmets, and all of them are half helmets. (Source: Ministry of Public Security)

For electric bicycle drivers, generally B-Type helmet with 3C certification is enough. A complete driving helmet generally contains the following components: helmet body, face mask, inner lining, reflecting board and safety buckle.

Helmet Body

The material of the helmet body is generally ABS or PC, and most of the molds only have one cavity. Few molds are of 2 cavities. Generally, the injection molding machine model suitable for the mold of 1 cavity is 280T. That suitable for mold of 2 cavities is 400T. The cycle time of the ordinary injection molding machine is generally about 30 seconds. However, our TLE series servo injection molding machine, which are fast machines, can generally reduce the cycle time to about 18s.

Helmet Lining

The main material of the helmet lining is generally PE, and most of the molds are 1 out of 1. It is also possible to achieve 1 out of 2. In general, you can choose injection machine of 280T for the mold of 1 out and 400T for the mold of 1 out 2.

Helmet Mask

The main material of the helmet mask is generally PC, and the mold is mostly of 1 cavity. It is recommended to use the injection molding machine of 220T. The cycle time is about 20 seconds. The requirements for the mold are high and the mold must be polished. The injection response speed of the injection molding machine is also required to be higher.

Safety Buckle and Reflecting Board

The safety buckle and reflecting board are relatively small. The general mold cavity number can be 12. The injection molding machine model is recommended to be 150T. The general cycle time is about 20s. The cycle time of Taili fast machine TLE series servo injection molding machine can be shortened to about 15s.

At last, I suggested Mr. Li, āif you really want to do the business, you should make a good helmet that really meets the standardsā. The lessons of the meltblown fabrics and masks are in front. The price of meltblown fabrics below level 90 have dropped to around 30,000 yuan. The price of meltblown fabrics at level 95 is still above RMB 600,000 and still have a big market. Manufacturers for meltblown fabrics below the level of 90 have been sorrowful. but manufacturers of high-end meltblown fabrics are still receiving many orders.

Taili Plastic Machinery has been helping customers to solve the problems and improve profit margins. It is the rule we always remember: selling machines is only the beginning of cooperation.

|

China

China

China

China