2018-4-27

Keywords: plastic food container, thin-wall, package, injection molding machine, high-speed machine

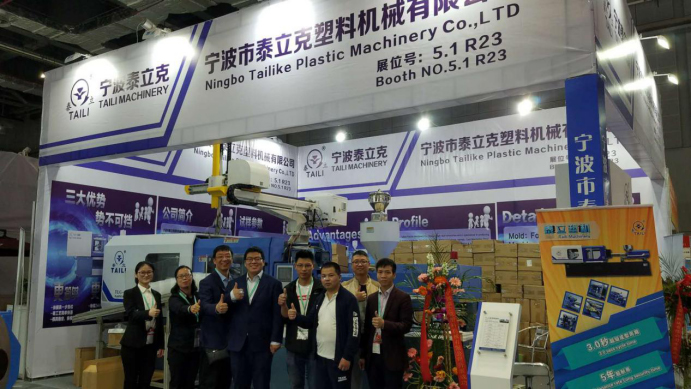

April 27-29, Taili High-Speed Injection Molding Machine was exhibited on the AsiaŌĆÖs greatest plastic and rubber trade affair-Chinaplas. The machine struck the audience with its great performance and supreme production rate. The 1 of 2 mould was designed for 650ml food container. The cycle time was reduced to 3.4s and the production per hour reach 2200 pieces.

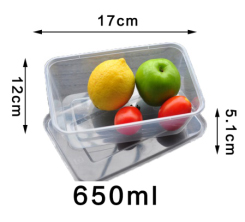

Machine Type: TLG-280

Products: 650ml square food container

Product weight: 12g

Material: PP

Cycle time: 3.4s

Mould-opening time: 0.9s

Mould-closing time: 0.9s

Repetitional positioning accuracy: 0.1mm

Product profile:

Taili Injection Molding Machine is leading among the peers on the aspects of power consumption, production rate and product quality, which win a lot of praises from our customers. ItŌĆÖs our staffŌĆÖs persistence in machine quality and continuous insistence on innovation, that won favorable comments from the audience.

The raw materials for plastic food container are mainly PP(Polypropylene) and PS(polystyrene), which are non-toxic, tasteless and odorless. PP is softer and the use temperature ranges from -6Ōäā to 120Ōäā. Thus, itŌĆÖs suitable to take hot food and heated in the microwave oven or the steam tank. The modified PPŌĆÖs use temperature is from -18Ōäā to 110Ōäā. The products made from this kind of PP can not only be heated in the temperature over 100Ōäā but also be stored in the refrigerator.

How to choose a suitable injection molding machine? How choose an injection molding machine with high production at a low cost? We will give you the best answer. Below is the measured data.

| |

1000ml

lid |

1000ml

lid |

1000ml

box |

1000ml

box |

| Machine Type |

TLG-400 |

normal machine |

TLG-360 |

normal machine |

| Clamping Tonnage |

4000 |

4000 |

3600 |

3600 |

| Material |

PP

(Polypropylene) |

PP

(Polypropylene) |

PP

(Polypropylene) |

PP

(Polypropylene) |

| Cavity |

8 |

8 |

4 |

4 |

Product Weight

(Same Mold) |

7.5g |

8g |

16.0g |

16.5g |

| Cycle Time (including fetch time) |

4.8s |

7.5s |

4.8s |

5.8s |

| Production Increase |

36% |

- |

20% |

- |

| Power Consumption |

0.00065 kW┬Ęh /g |

0.0007 kW┬Ęh /g |

0.00065 kW┬Ęh /g |

0.0007 kW┬Ęh /g |

Taili high-speed injection molding machine can decrease the product weight with the same mould applied (we can also increase the product weight by the way of pressure maintaining). At the same time, the production will increase by 20%-30% and power consumption will be reduced, which make our machine a better choice for you than other normal high-speed machine (producing food container). |

China

China

China

China