Cable Ties Machine

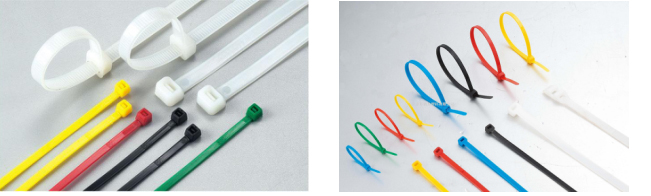

Straps are also called straps, locking belts, which, as the name suggests, are straps used to bind things, some of which do not have the function of stopping or retreating and some are detachable. Cable Ties have the advantages of fast binding, good insulation, self-locking fastening, easy to use and so on.

I. Performance of Cable Ties

The belt is made of UL approved nylon-66, fire proof grade 94V-2, which has the advantages of acid resistance, corrosion, good insulation, not aging, light weight, safe and non-toxic and strong bearing capacity. Operating temperatures range from 40 to 90 degrees below zero. Comprehensive mechanical properties are far superior to general engineering plastics, thus it is an ideal substitute for copper, stainless steel and other non-ferrous metals.

II. Categories of Cable Ties

According to the material, the cable ties can be divided into nylon band, stainless steel band, spray stainless steel band, etc., which are often used in mechanical and electrical products cable, computer, electronic products, automotive wire harness, etc. According to the function, the cable ties can be divided into common band, recoverable band, tag band, fixed locking band, pin type band, heavy tension band, etc.

III. Function of Cable Ties

Due to the particularity characteristic of thin-wall, the injection molding process of cable ties is of relatively large-scale. The production process and material choosing are all very particular. the general new manufacturers need a very long groping process to produce qualified products.

Cable ties can be used in electronic factories, bundled television sets, computers and other internal connections, lighting, electrical machinery, electronic toys and other products of the internal wiring, mechanical equipment oil pipeline fixation, ship cable lines fixation. It is widely applied in our life.

IV. Our Cable Ties Machine

Our cable ties machine have the following five advantages:

(1) The PA specialized screw and the material tube group are applied. Thus, the plasticizing effect is good and the glue melting speed is fast. The drainage and gas exhaust design has been made in the material tube group to guarantees the product quality;

(2) Rectangular formwork design is more suitable for the production of cable ties;

(3) Optimized design of hinge structure is applied, which can reduce the opening stroke and greatly reduce the opening time for the tie die.

(4) Template, sheet metal, machine hinge and other components are strengthened to ensure the service life of the machine.

(5) Oil pump and motor are increased so that gelling speed is faster. |