Key Word: Taili Plastic Machinery; Taili Plastic Machinery-Capacity Improving Expert; Efficient; Stable

In the process of producing injected plastic products, both mold and injection molding machine are essential. We¡¯ve come across many cases that the suppliers of injection molding machine and mold shirk the responsibilities to each other when facing the production of defect products. It¡¯s funny to see what¡¯s in purchasers mind is: I don¡¯t care whose responsibility it is! Can you just make it back to normal work right now?

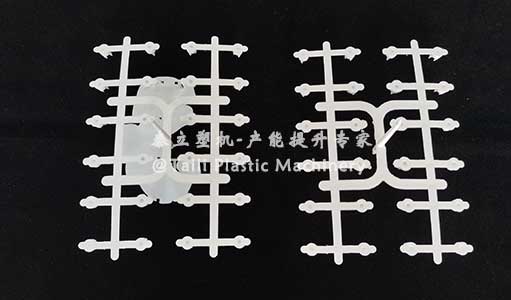

In my recent visit to a friend¡¯s factory, he complained to me a similar problem. His main product is the maker pen. There are almost 15 injection molding machines in his factory. The machine adjusting technician and the mold supplier quarreled a lot that time. The mold runner is shown as below.

The mold supplier believed that there could not be any problem with the mold. He has been making the mold for marker pen for many years and what he keeps is such runner. Thus, it should be the machine adjusting technician¡¯s responsibility rather than his.

The machine adjusting technician is mad at his words. As he said, If all the product are lack of material, he can increase cycle time and injection pressure. If all the products have flash, he can reduce the injection pressure and time. But some of the product appear to have flash while some products are lack of material. How can I adjust it? The best way is that you repair the mold and change the runner.

Their mold supplier and adjusting technician have been adjusting for this product for several days, and there has been no big change. When I got the product and had a brief look, I suggested to my friend that you can assemble this mold onto TL170 injection molding machine of Taili Plastic Machinery to have a try. I guessed it was neither a mold problem nor a process problem. I believed it had something to do with the design concept of the machine.

This friend had bought several Taili injection molding machines and took a try immediately according to my suggestions. The result turned out to be good as there is neither flash nor lack of material. Then both the mold supplier and adjusting technician were happy for neither of them should take the responsibilities.

I explained to my friend that there were many reasons for product defects. Compared with other brands, our injection molding machine has faster injection speed and higher mechanical precision, which is specially designed for this kind of thick-wall product. If you come across the similar problem in the future, just have a try to apply the mold onto Taili plastic injection molding machine and you may find the difference!

Taili Plastic Machinery always keeps in mind that what a good injection molding machine factory should do is to help improving the capacity and boosting the profits, rather than offer the similar products the customers need. This is also what Taili Plastic Machinery keeps doing.

Follow Taili Plastic Machinery and we will share more with you.

|