Key Word: Taili Machinery; injection molding machine; Taili Machinery-Capacity Improving Expert; Mold Choosing

Some people always wonder why peers can sell the same product at a price far below the cost price, and still make a lot of money. However, their products are always rejected by customers because of the high price. Taili Machinery will answer the question one by one based on more than ten years of production experience of injection molding machines. Let’s first start with mold.

There are tens of millions of injection products and various mold suppliers. As a manufacturer of plastic products, how to choose a reliable mold supplier is extremely important. As an experienced person who have been in the business for many years, you may say that the mold choosing is very simple. Choose the material first, and then the price. But take the core material P20 for example, do you know how many different specifications there are? There are many places where mold makers can contribute while guaranteeing profits.

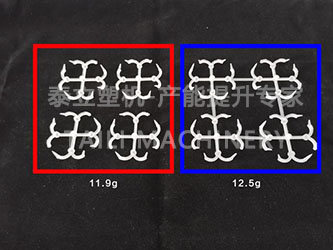

Taili Plastic Machinery tells you that you must find a good supplier of injection molding machine in order to find a good mold. You may say that “the injection molding machine is not important.” “I have used a lot of injection molding machines and they are similar.” But Xiaotai wants to tell you that you do make a big mistake. Good injection molding machine suppliers will tell you what molds and materials to use to maximize the performance of the machine and reduce the cost to the lowest. For example, Taili Plastic Machinery recently encountered a mold which is designed for a 1-of-16 syringe cap. The cold runner is designed as shown in the below image.

At the beginning, the material head received by the customer is like the left side shows. Four products are separated. The total weight of the hopper is 11.9g and the injection cycle is about 25s. The biggest problem is that the cycle time is long and the material is easy to stick under the mold, which easily leads to the occurrence of stamping. Later with the suggestion of the technical staff of Taili Plastic Machinery, the material was changed as shown on the right side. The total weight of the material channel was increased to about 12.5g, which was about 0.5g more than before. However, after such improvement, the cycle time is reduced to about 15 seconds, and no stamping phenomenon occurres, and the product yield was greatly increased.

From this, it’s obvious that choosing the right injection molding machine manufacturer and mold manufacturer will promote the profit margin!

|

China

China

China

China